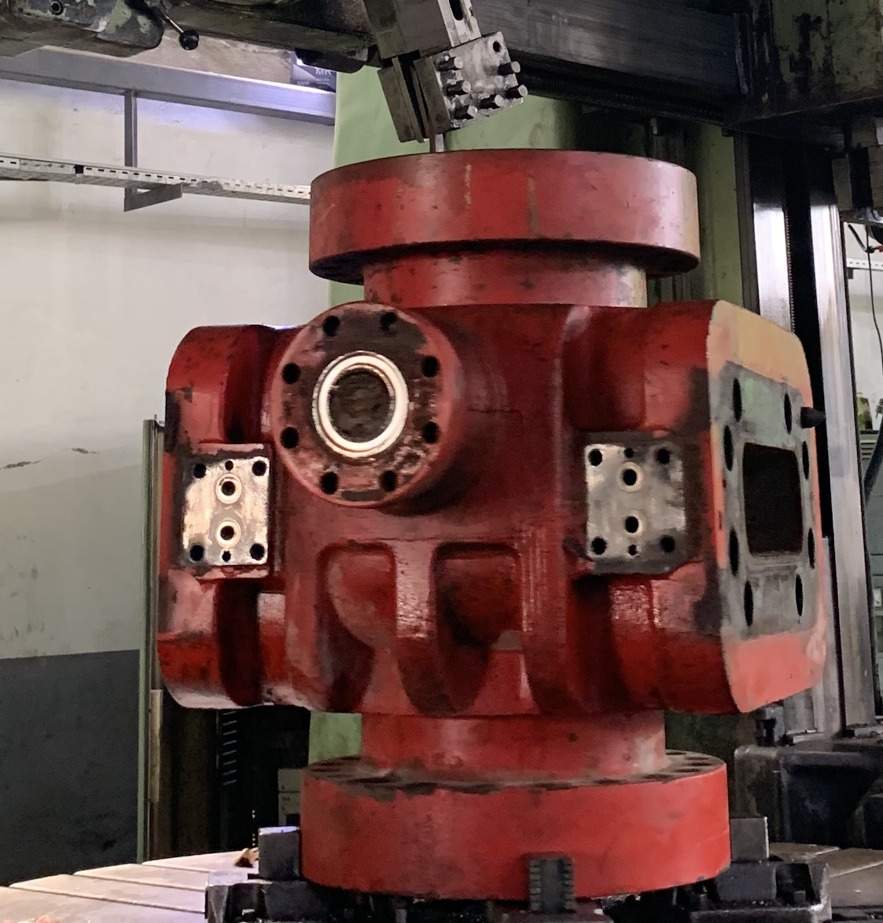

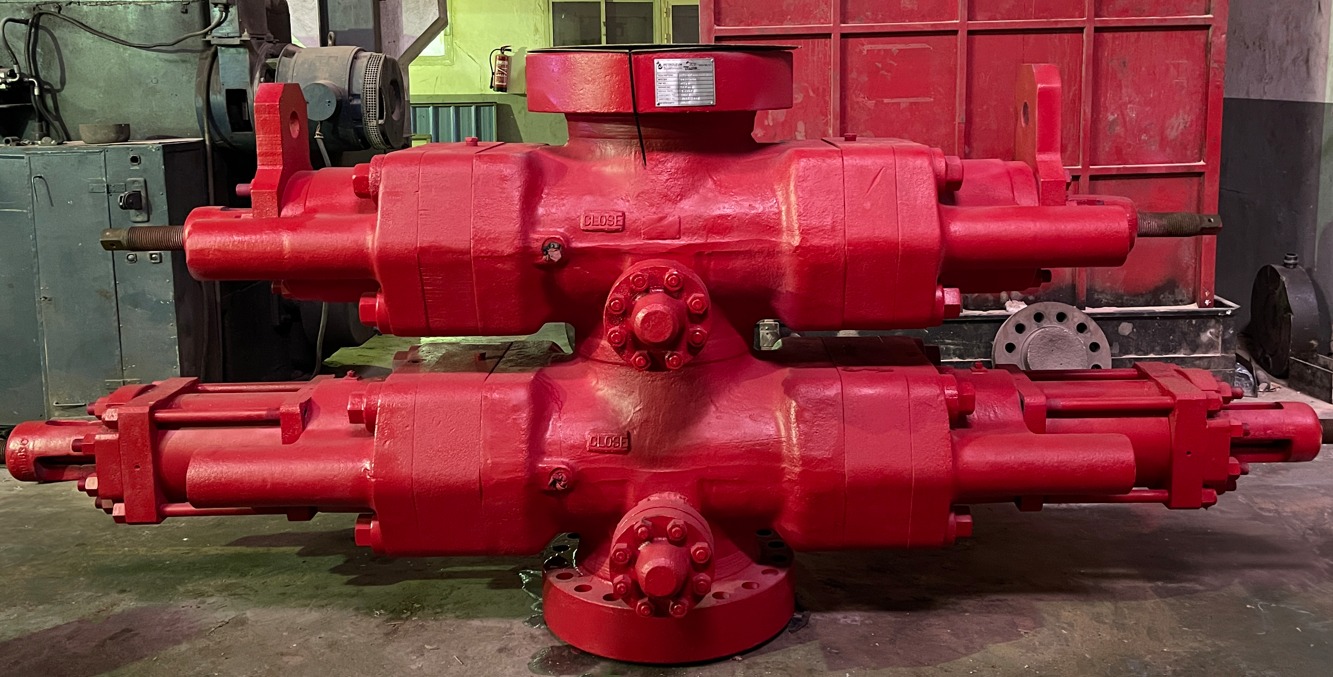

BOPs Re-certification

Testa and Toni is an authorized repair facility for OEMs and is capable of the re-certification of all types/ sizes/ models of any BOP of any make ranging from 7 1/16”-5 K to 30”-1K Rams & Annular BOPs, directly to drilling contractors to meet their 5-years API Certification schedule.

With more than 90 years of experience and period- ically calibrated state of art equipment & machines, we ensure the highest acceptable tolerances & quality.

From simple redress to full re-certification of your pressure control equipment, our proven track record of excellence in design, manufacturing, and service will help you keep your operations running at maximum efficiency 24/7.

Types of repairs offered:

- Working class repair

- Premium class repair

Capabilities:

- Heavy Mega Vertical & Horizontal Lath machines

- Heavy Mega Boring machines

- Twin-wire sub-arc welding (SAW) with motorized, rotating table in addition to manual welding (TIG-MIG-SMAW) with capacities 100% weld repair (Inconel, STST, or base-metal inlaid),

- Drilling/milling/threading Heavy Machines

- Post-Weld Heat Treatment (PWHT) in our state of art computerized stress relief Furnace.

- Positive Material Identification (PMI)

- Disassembly, inspection (NDT, MPI, hardness, dress up, polish, re-tap stud holes, dimensional Inspection, and re-assembly

- Xylan coating internal & external

- Blast prime & paint

- Hard chrome plating (re-chroming ram shafts, locking screws, and cylinders)

- Computerized BOP pressure test unit with our state of art underground test bay

- Testing capabilities up to 30,000 PSI

- Hydraulic test unit up to 4,000 PSI

- Online live transmission of the pressure test results globally for all BOP stacks

- In house preservation procedures as per customer requirements

- Supply of rubber seals & packing elements for all sizes & models for any BOP

- Rental capabilities

- Ram blocks re-certification