WELL CONTROL DIVISION (DRILL THROUGH & PRESSURE CONTROL EQUIPMENT)(API 16A)

Testa & Toni (T&T) is a full service Blow-Out Preventers and valves servicing company.

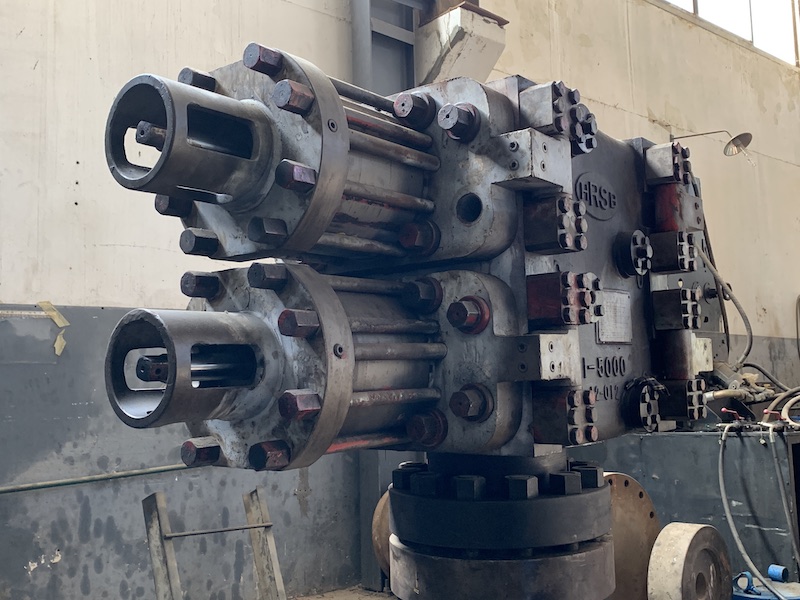

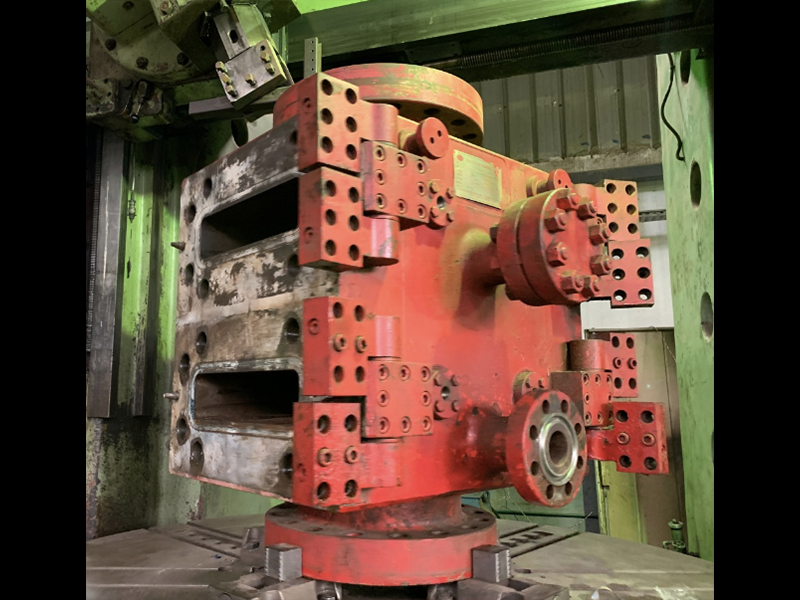

Testa & Toni repairs and certifies all types, sizes and OEM Models of BOPs.

We re-certify and manufacture all types and sizes of Drilling Spools, Mud Crosses, Off Shore Drilling Risers and Adapter & Spacer spools as per API 16 A.

For more than 90 years, T&T’s expert team has maintained a reputation as a key source of excellent services to the oil & gas industry for repairing, maintaining and re-certifying : Ram Blow Out Preventers (Single & Double BOP), Annular BOPs, Marine Risers Systems, Surface & Subsea equipment, Well Head & Christmas Tree Equipment, Manifolds, Valves, Chock and Kill Manifolds and all Drill Through Equipment providing warranty and COC backed by OEM design, Engineering and API standard returning the equipment back to the service level for all leading manufacturers’ equipment major brands.

All Tests, Disassembly, Inspections, Welding, Post–Weld Heat Treatment, Repairs, Machining, Assembly, Pressure Testing, Sand Blasting and Painting are performed In-House.

Our range covers the whole service spectrum from regular maintenance, pressure test to re-certification according to API 16A and API 16AR requirements. T&T’s Team who worked closely with equipment owners and OEM for years are highly experienced with the ability to repair all types of BOPs. Our comprehensive engineering capabilities and Technical Library guarantee that all repairs are performed with full perfection.

It is necessary for T&T to review all original documentation and service history of the BOP prior to commencing initial inspection. All BOP services are accompanied by a full documentation package offering full traceability of services carried out by Testa & Toni (T&T), through our :

- Heavy Mega Vertical and Horizontal Boring machines

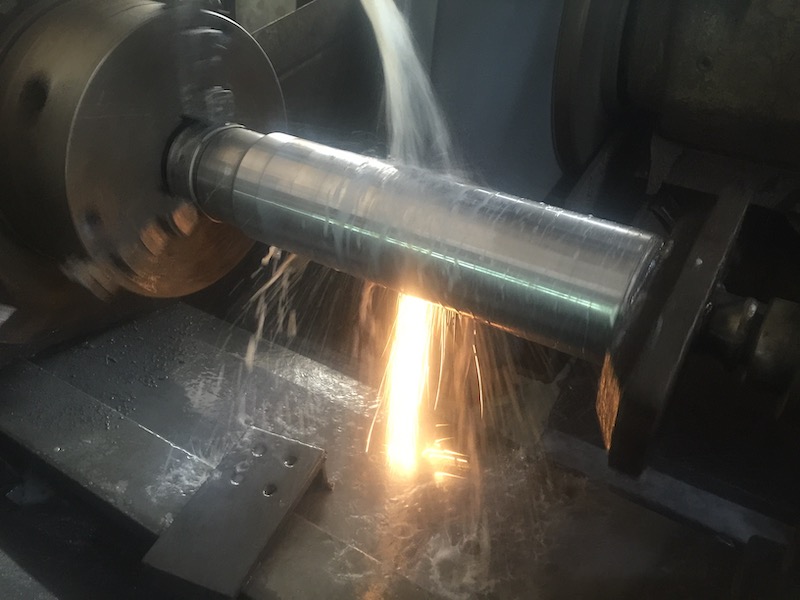

- Heavy Mega Vertical and Horizontal Lath machines

- Twin Wire Sub Arc welding with motorized rotating table, Manual Welding (TIG – MIG – SMAW with capacity to weld all types of metals.

- Drilling/Milling/Threading Heavy Machines

- Post-weld heat treatment for Stress Relief in our state of Art computerized Heat Treatment Furnace

- Disassembly/ Inspection (NDT , MPI, Hardness & Dimensional) /Re-assembly

- Hard Chrome plating (Re-Chroming Ram Shafts, Locking Screws & Cylinders)

- Computerized pressure test unit (30,000 PSI) with state Of Art Underground Bay.

- Test BOP with our State Of Art Underground Test Bay with Hydraulic Test Unit up to 4000 PSI & Hydro-Static Test Unit with Pressure Capacity of 30,000 PSI

- Online live transmission of the Pressure Test results globally for all BOP stacks

All repairs, re-manufacturing and re-certification are completed at our API Q1; API 6A, 16A and 16 AR certified and licensed facility.

Servicing our client’s BOP’s at an industry respected and API approved service facility gives confidence that all repair works are being undertaken in accordance with a quality system that is certified by the Oil and Gas Industry’s highest quality certification API.

Our goal is to return your equipment to industry standards minimizing your down time when servicing or repairing your BOP whether you need:

- Reconditioning to OEM Specifications

- Re-conditioning to achieve specified operational requirements

- Repairing and servicing to resolve identified issues or malfunctions